DESIGN BUILD

On a Grand Scale for Architecture, Entertainment and Sports

DESIGN & ENGINEERING

Our full service design and engineering teams work to expand the boundaries of imagination.

We collaborate with you to create the extraordinary sensation that one gets from experiencing something truly spectacular for the first time.

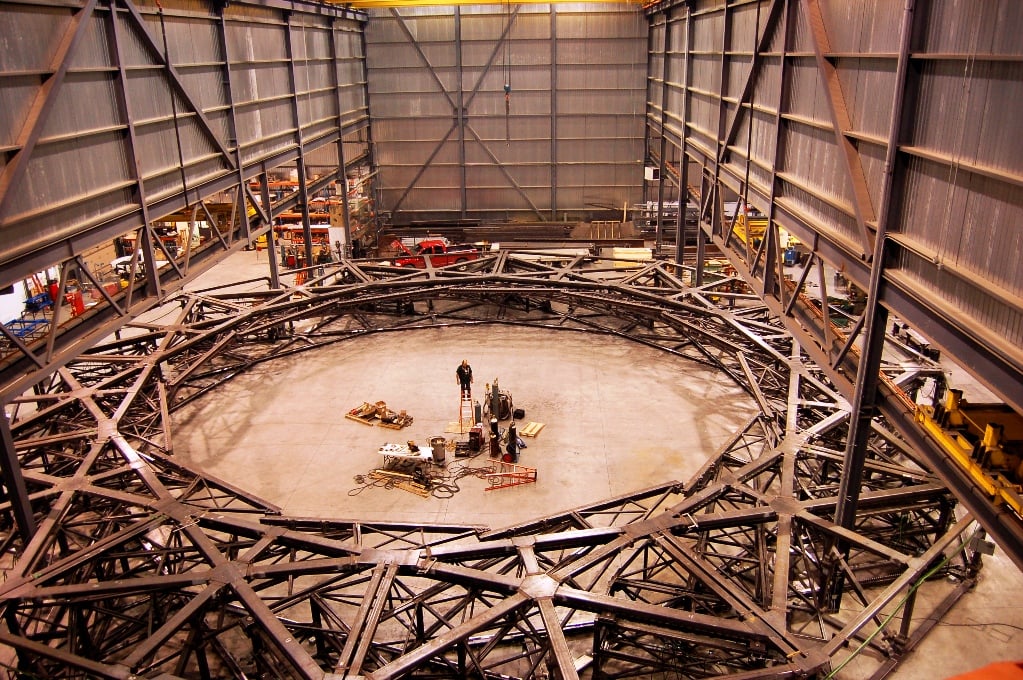

MANUFACTURING

The largest most complex structures and machines in the industry are fabricated in our Montreal facility.

Certified structural and decorative steel fabrication, full service machining capabilities, themed entertainment and theatrical scenic finishes, automation & controls integration, full factory testing capabilities.

INSTALLATION

World wide reach with a specialized workforce of experienced project managers, supervisors, and dedicated field crews which have delivered projects in over 30 countries.

From lower Manhattan to Ashgabat, we deliver turnkey projects all over the world.

This includes the possibility of rental of specialized scenic equipment for large scale staging projects, with inventories in Canada and in the United Kingdom.

Let’s talk about your project

For inquiries about pricing, project delivery capabilities, or bringing your most ambitious ideas to life, please contact our sales team at sales@show-canada.ca

PROJECTS

Featured Projects

ABOUT

Jean Labadie

President & CEO

With a passion for engineering, combined with a rebellious spirit, Jean enjoys taking on the largest and most difficult projects worldwide.

Show Canada Industries

Ability to execute the entire project in house, from creative design work, to fabrication with with full FAT demonstrations for the client in our factory, to installations (turnkey) with coordinated field teams serving in countries all over the world.

Integrated multidisciplinary teams include inventive, creative and experienced designers to translate visions quickly and efficiently.

Engineers with a variety of expertise including structural, mechanical, civil, electrical, and automation are able to meet demanding challenges submitted by client’s architects and consulting teams.

Complete specialized workforce (i.e. craftspeople, blacksmiths, sculptors, welders, mechanics and technicians).

A manufacturing facility in Montreal, which designs and manufactures spectacular scenic elements. Many designs include movement, producing large automated structures.

Flexibility to respond to contingencies and always “deliver the goods on time”. Show Canada adheres to a disciplined project management process.

Show Canada maintains the highest standards of safety, and we value integrity in all our relationships. Our aim is to enhance the themed entertainment and sports worlds each time we have the honor to perform our craft.

CONTACT

Careers

Join our team of artisans, draftsmen, designers, engineers, welders and project professionals.

Head Office

5555 Maurice-Cullen,

Laval (Quebec), Canada

H7C 2T8

Phone: +1 450 664-5155

Email: info@show-canada.ca

Human Resources: rh@show-canada.ca

Sales : sales@show-canada.ca

Middle East Office مكتب الشرق الأوسط

Show Canada Industries (SA) شو كندا للصناعة ( السعودية )

US: +585 314 6355 الولايات المتحدة الامريكية :+5853146355

KSA: + 966 55 964 4429 المملكة العربية السعودية : +966559644429

email: info-sa@show-canada.sa

Tel : +966 114568110 Ext:101 تليفون : +966114568110 تحويلة : 101

Fax : +966 114568110 Ext:108 فاكس : +966114568110 تحويلة : 108

Ground Floor, Building no – 8037, Dumyat Street

P.O. Box – 2659

Al Taawun District, Riyadh 12477 , KSA

Peter Hoffend

David Boulay

Yee Ming Louie

Pierre Marchand

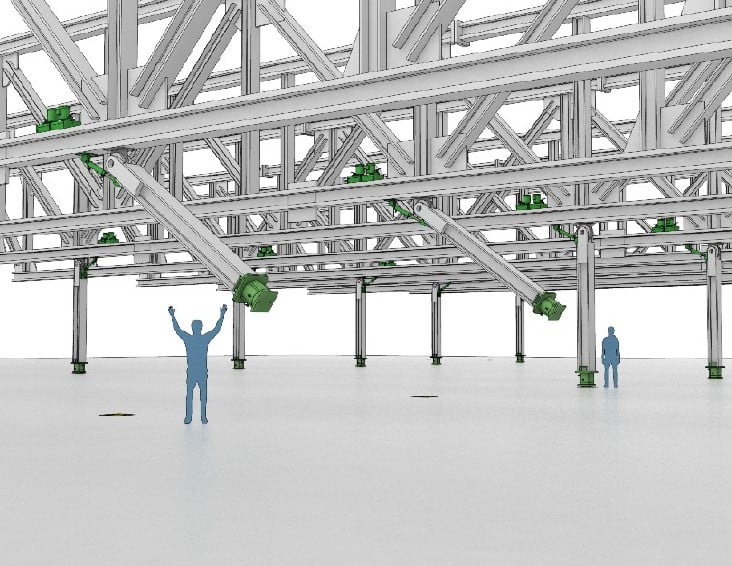

Gantry Grid System – Chase Center

We were selected to design and build a movable gantry grid system.

The gantry grid system consists in two independent steel structures (named north and south gantry) mounted on four bogies each. These two structures can drive along two runway girders hanged to the arena roof. The main objective is to infill the very large hole in the arena roof structure required for the vertical mounting scoreboard and thus provides attachments in the center of the arena for equipments during music or theatre shows.

The driving system which has been chosen is a Serapid linear beam. There are four platforms on each corner for Serapid motor maintenance.

Organic Bar Wall – Seminole Hard Rock Hotel & Casino

Located in the center of the hotel lobby is the Oculus Bar at the Seminole Hard Rock Hotel & Casino Hollywood. Boasting an open layout, guests have panoramic views of the resort’s flagship attraction, the Oculus.

We supplied and installed a fiberglass wall structure around the central bar (Oculus Bar). The scope of work also included the drawings, the fabrication of the structure and the installation of the fully finished structure.

The wall consists of a rigid foam with lattice structures covered with reinforced fiberglass (FRP). The wall is composed of 4 main sections. Each structure is anchored in the concrete on the ground by Hilti anchors into steel plates.

Each wall consists of 4 sections about 8 feet wide and have been assembled and finished on site. The sections of the FRP structures were painted in our workshops and on site once the assembly was completed and the finalization of the joints. FRP structures are also fire resistant.

The north wall has a curvature of 57 linear feet and is fixed to the ground in 6 places. The FRP structure has a height of 12′-8¨ inches at its highest point.

The south wall measures about 82 linear feet, excluding the ramp, is maintained by 7 anchors on the ground. The highest point is 12′-8 ”.

The west wall is about 42 feet long, excluding the ramp. Done 11′-5 ”. The west wall has 3 ground anchors.

The wall is approximately 30 feet long with a maximum height of 6′-6 ”. The wall has 3 anchors on the ground.

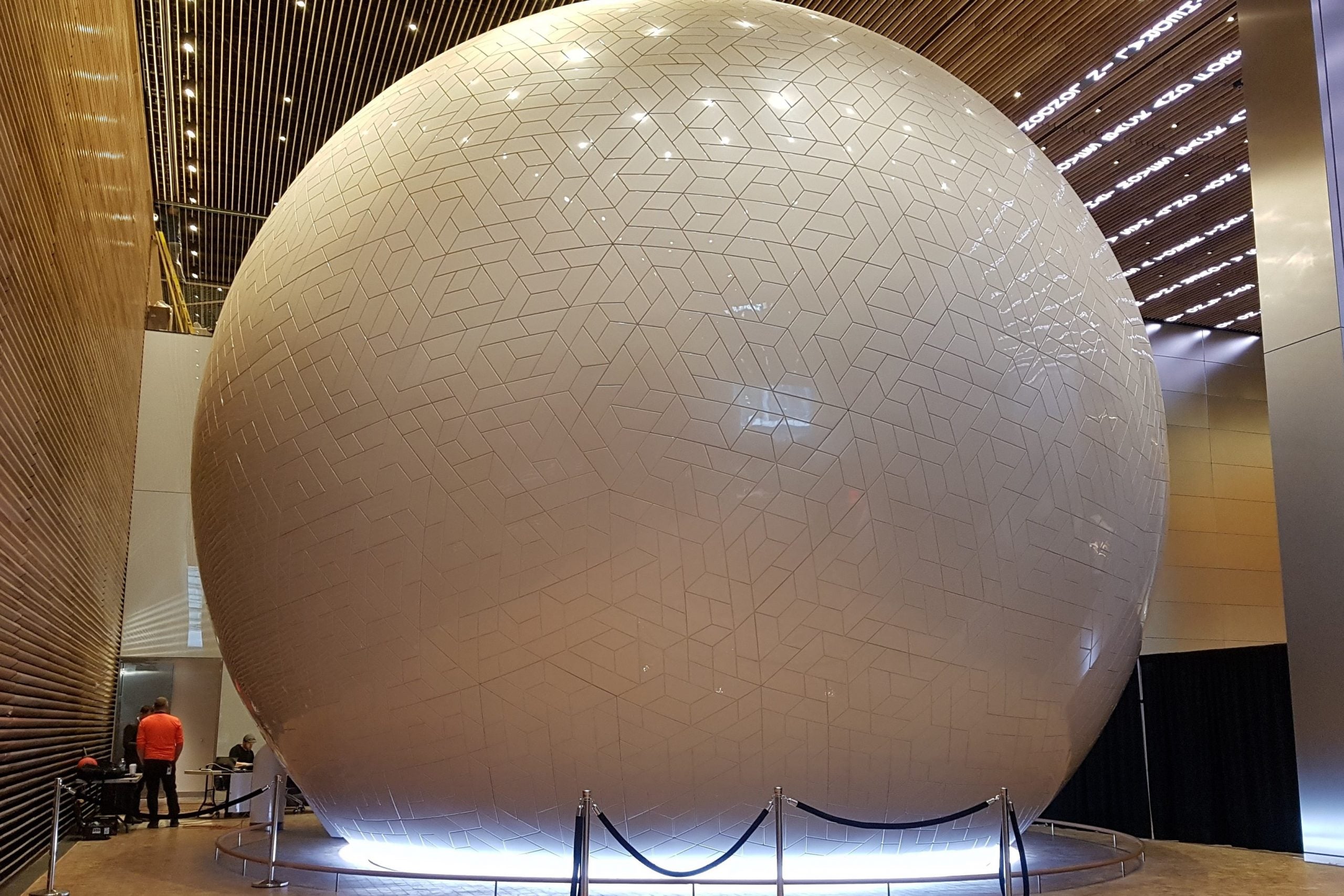

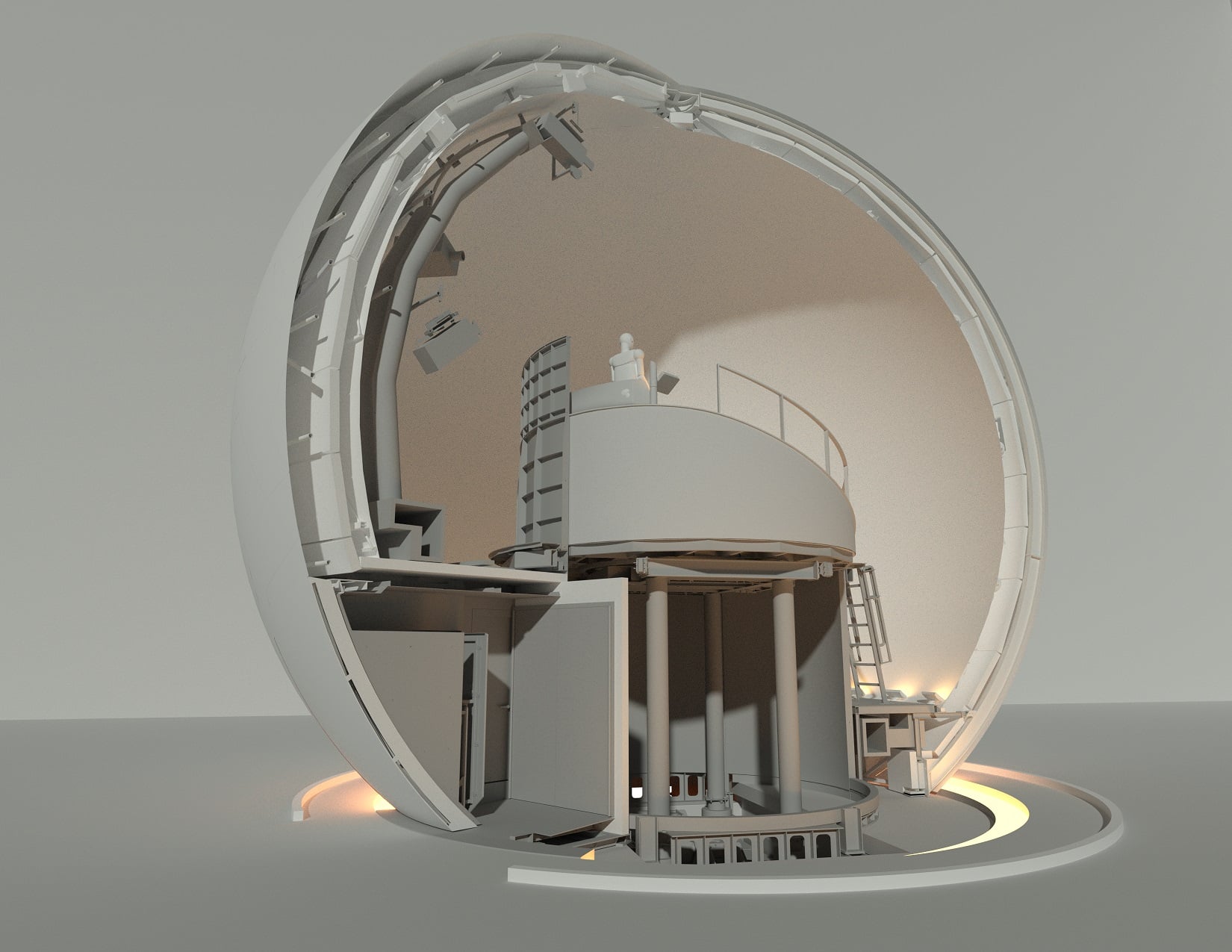

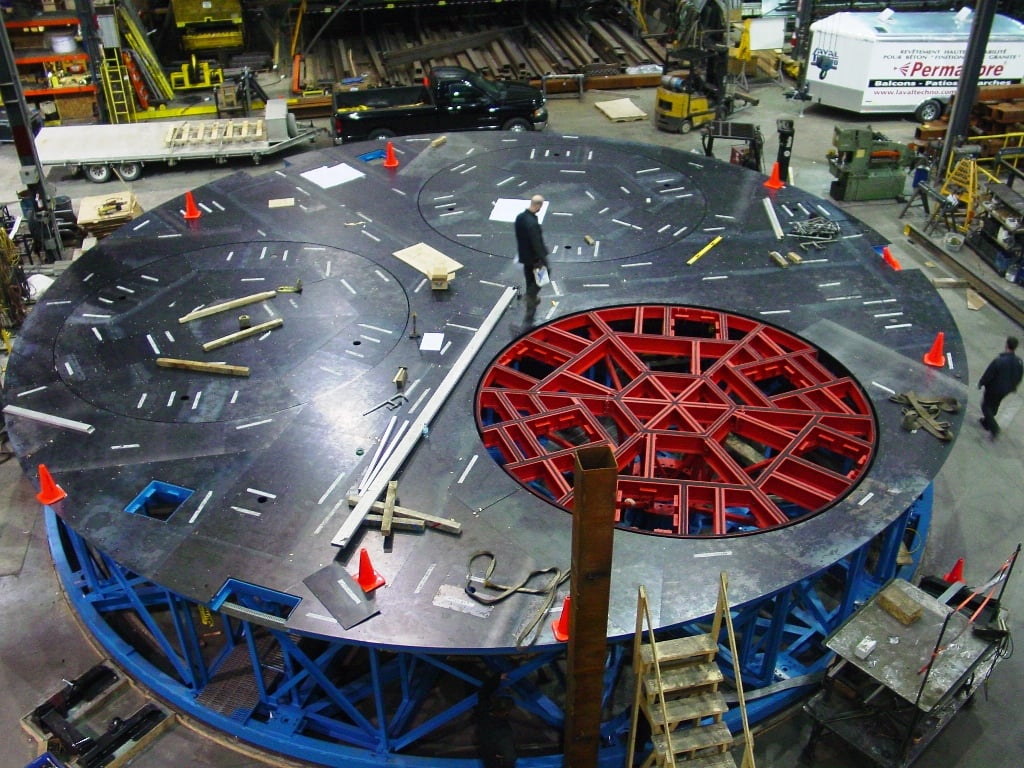

Automated Doors, turntable & Lift – Universal Sphere at the Comcast Technology Center

We were chosen to design and build three main elements of the Universal Sphere. The automated doors, the lift and a turntable.

The Comcast Sphere is a 39ʹ outside diameter sphere, free-standing, permanent structure constructed on the 2nd floor concourse of the Comcast Technology Center, in Philadelphia. It contains a show dome and a viewing platform designed for up to 30 patrons and 1 inside operator.. The viewing platform is mobile, rising up 10ʹ and rotating 180 degrees into an optimum viewing position; it lowers down to exit level at the end of the ~5-minute presentation.

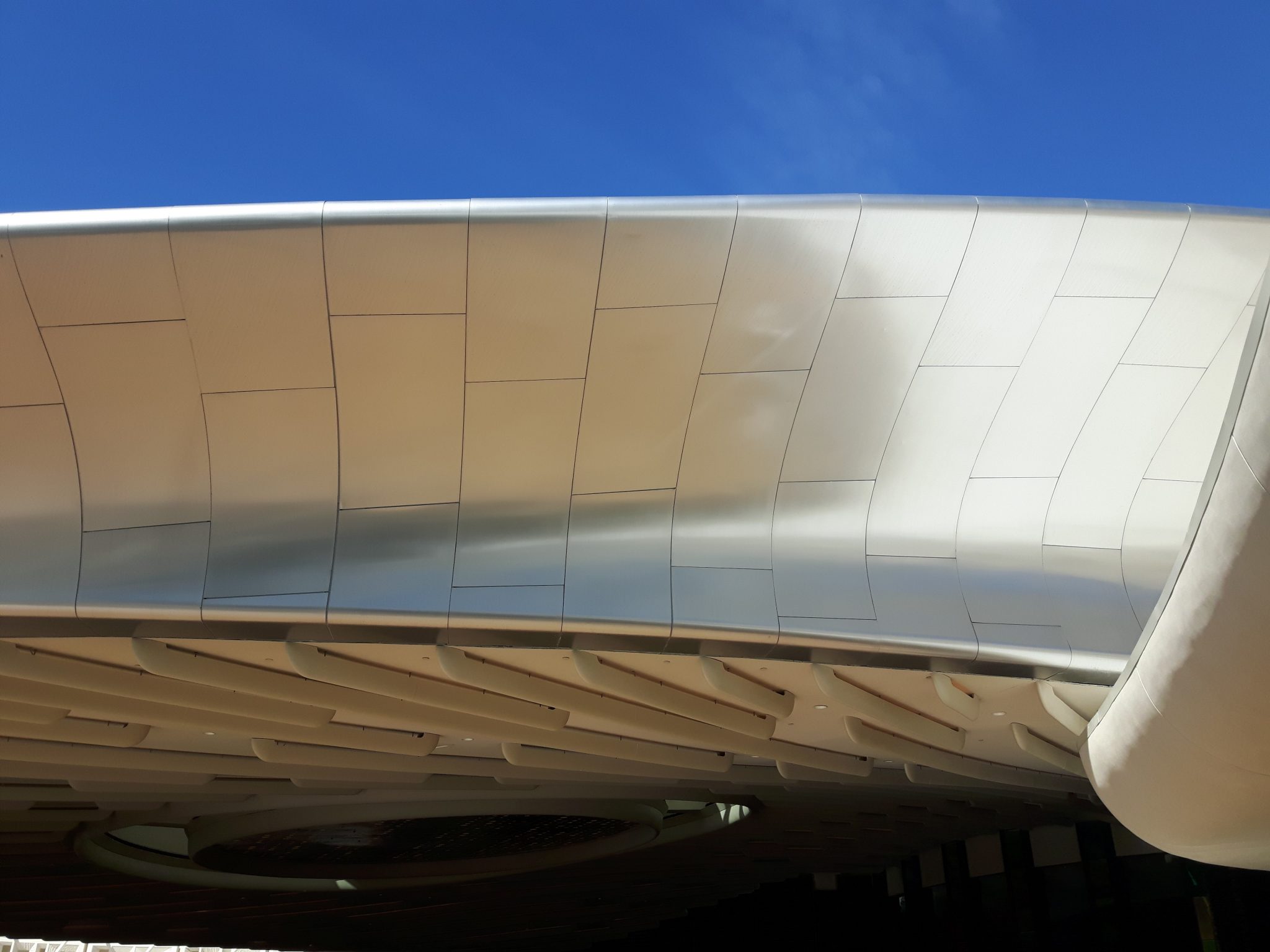

Porte-cochère – Seminole Hard Rock Hotel & Casino

The “Porte-cochère” is a decorative roof element above the main entrance to the Seminole Hard Rock Hotel & Casino in Hollywood, Florida.

The roof surface is composed of 30,000 square feet (2,8000 square meters) of double curvature stainless steel plate with a custom finish.

The roof is subject to extreme ambient temperatures and hurricane winds. The stainless-steel plate is attached to aluminium and galvanized structural frames hidden within the element, which in turn are fastened to the building structure. All design, engineering, fabrication and installation were performed in-house by Show Canada Industries.

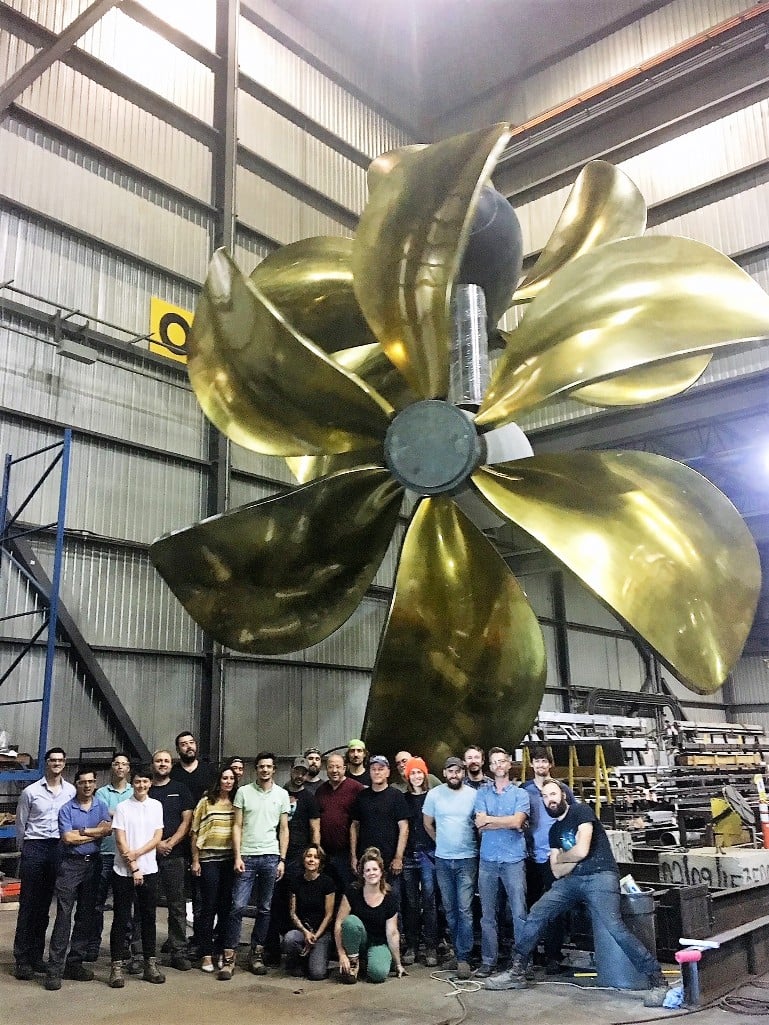

Automated Propellers – Miami Cruise Terminal

The RCCL Cruise Terminal in Miami is hosting a 15000 lbs, 56 ft tall, gold chromed kinetic sculpture as the principal attraction of the main entrance.

The assembly consists of a pair of propellers, each with 6 blades and a diameter of 27 ft rotating over a public area (with Industry Standard Safety Factors incorporated).

Both propellers rotate around a 24 in diameter mast as well as around their own axis at the speed of 3 RPM. A single fixed speed gear motor drives the rotation of the mast and the rotation of both propellers.

Everything was produced in-house in our Laval workshop and then shipped to be installed on site by our team of experts.

Spine Canopy – Seminole Hard Rock Hotel & Casino

Suffolk Construction chose us to design and build an awning.

The Canopy provides a fixed cover formed by a steel structure with a wood shingle roof.

26 Painted steel columns made in a tree shape from straigth HSS 16 & 6 ” dia with average of 6 main members and some secondary.

Cabanas Thick Screens – Seminole Hard Rock Cafe

At the Hard Rock hotel and casino resort, ten (10x) Bora-Bora cabanas have been constructed in the east pool area of the complex. Two configurations of cabanas have been made, the single and double configurations. Our mandate was to construct thick screens for four (4x) single cabanas 20’ X 20’ and six (6x) double cabanas 15’ X 20’.

The scope of work is to provide and install the movable screens, the fixed screens and the filler walls on each cabana according to their specific configurations.

Screens

The screens are composed of a 1/4’’ thick Aluminum sheet. The sheet has been cut using the laser process to reproduce the artistic pattern asked. Also, the exterior of the aluminum sheet has been coated with a bronze powder coat finish. This finish is composed of three layers: Transparent Copper 49/63130 over Chrome OGF 49/91312 with a clear top coat finish 49/00530.

Also, the screens have been designed in three sizes according to their location and functionality.

Frames

The frames are composed of an aluminum frame coated with the same process as the screens. The structure has been designed in such way that no screw or weld will be visible by the customer. To do so, the inferior part of frame has been installed using a locking system and the superior part of the frame has been locked using screws that have benn inserted on the top face of the frame.

Rails

The rails have been designed to support a maximum door load of 200 lbs. It is composed of Aluminum extruded jump proof box track fixed to the ceiling. A guide track has been fixed to the floor to align the inferior section of the screens during the translation movement. The tracks have been coated to obtain the same finish as the screens.

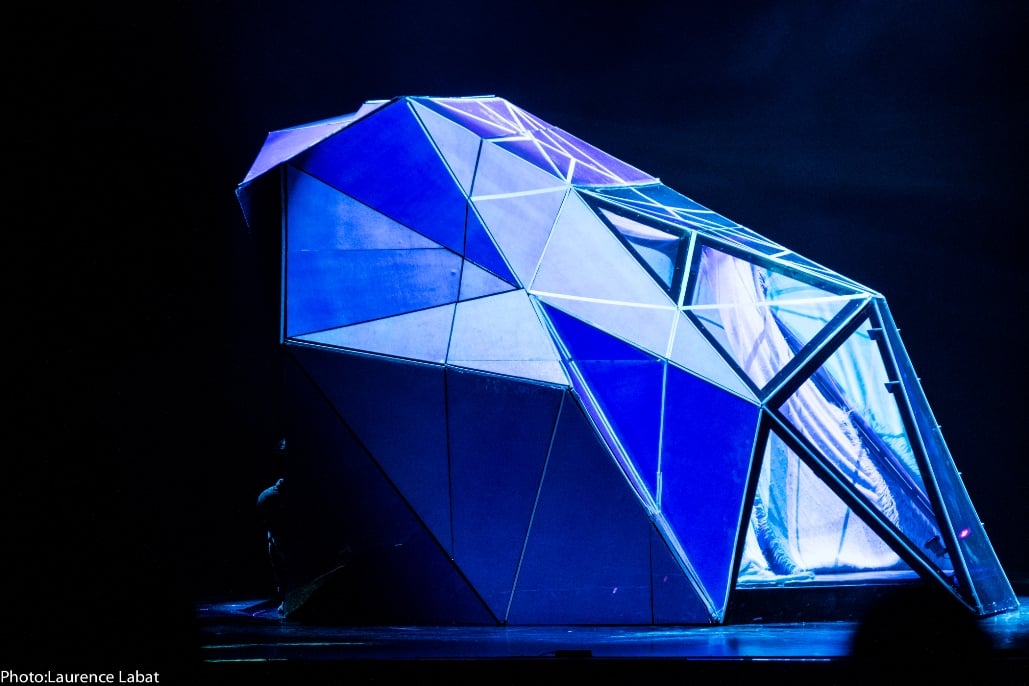

Diamond – Cirque Éloize: Serge Fiori – Seul Ensemble

Steel structure made of HSS painted matt black. The structure is removable in 4 sections. The transparent panels are made of 1/2 “clear lexan and the opaque panels are made of 3/4” Russian plywood covered with mirror films.

Each end of the chords is flattened and bent at the angle necessarily to the assembly.

The platform is also made of steel. It is covered with 3/4 “Russian plywood, each section of the platform is equipped with 6 Airpux wheels (2.5”) and 1 compressed air tank (6.5 “x 6.5” x 37 “).

The airpucks facilitate the movement of the structure by the technical team on stage

The idea of the 4 sections is (once disassembled (including the top) facilitates transport and storage backstage at half of the show

Tower Bleachers – Chicago Shakespeare Theater

Designed by Chicago’s Adrian Smith + Gordon Gill Architecture with the British theater consulting firm Charcoalblue, The Yard’s bleachers were a technical challenge for us. In fact, Charcoalblue gave us the mandate to finish the design and fabricate this complex structure while having a simple and easy to use operation system.

Each tower seats about fifty audience members on three gallery levels, tiered to maximize sightlines. Audiences access the gallery seating through a series of platforms and walkways from six sound and light locks, two on each level. To achieve a full 850-seat configuration, the Yard also features modular main-floor seating risers, with seats fabricated by Kirwin & Simpson in the United Kingdom.

To move the towers into a new configuration between productions, specially trained crew members insert air skids beneath each tower, and pressurize them to lift the towers a scant 3/8-inch off the ground. In this “floating” position, a three-person crew can move the towers.

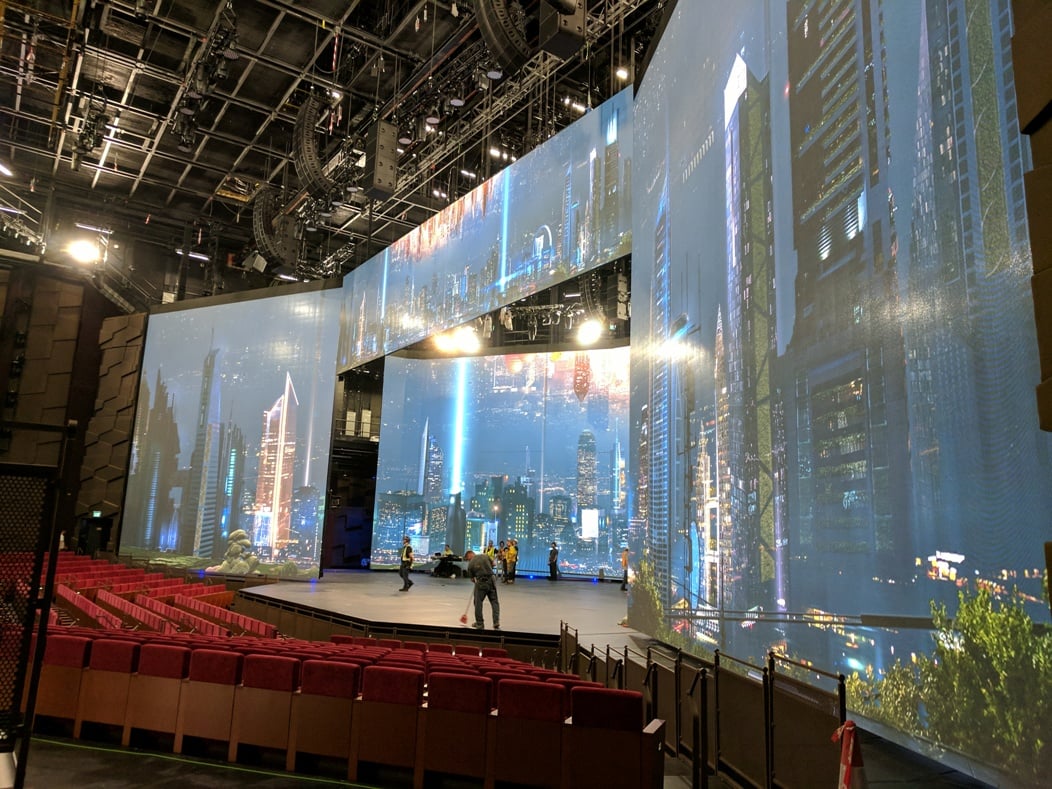

Theater Video Wall System

The MGM Cotai Theater is part of a multi-purpose performance space that can be configured for a wide variety of uses. A key feature of the performance space is the Theater Video Wall System (approximately 12m tall by 67m long), which includes two primary spatial configurations (Immersion & Proscenium) and a number of local access areas. On this project we have been contracted to engineer, build and deliver a system of moving/shifting Walls/doors and LED panel support. The system consists of seven major elements: The Static Wall structure, the Horizontal Sliding Wall, the Horizontal Sliding Platforms, the Pivot Walls, the Egress Panels, the Vertical Sliding Panels and the Header.

The Static Wall structure main role is to support the static LED modules, as well as some ot the moving LED wall elements.

The horizontal sliding wall, located in the center of the stage, moves away from the Static wall to create a way out through the wall. The sliding Wall has two independent bogey frames that are tied together with a single transition frame. The two bogey frames are actuated by a single electric motor and joined using a coupling shaft.

The two Horizontal Sliding platforms located at the low catwalk level, one on either side of the stage, just upstage of the Vertical Sliding Panels. When the Vertical Panels are raised, the platforms can extend onstage through the opening in the Static Wall Structure to create a cantilevered playing area. The two adjacent Vertical Sliding Panels, one on either side of the stage, travel vertically along guide tracks built into the Static Wall Structure and act as an open/close door for the Horizontal Platform. Each Vertical Panel has a “bogey” frame and a transition frame. The transition frame moves independently of the bogey frame and is capable of precise micro-moves to ensure alignment of LED modules. Each Horizontal Sliding Platform and each Vertical Panel is capable of being operated independently of one another.

The two pivoting walls are located each side of the stage. In the Immersion configuration, the LED modules align with the adjacent Static Wall LED modules. To create the Proscenium configuration, the pivoting walls rotate ±62° onstage to become the side LED wall sections. Each Pivot Wall is capable of being operated independently.

The four Horizontal Sliding Panels for Egress in the theater design, which travel away from the plane of the LED Wall up/offstage in order to create exit paths behind the LED Wall.

The proscenium Header is approximately 17.5m long and 4m tall. The header move up and down to complete the proscenium configuration with the pivot walls when they rotate onstage to become the side wall sections.

Wynn Macau – Dragon Tower structures

Show Canada was commissioned to build the dragons in 2013. The custom dragon tower structures and the bull wheel enable the cabins to travel around a curve and consequently make the ride around the lake possible. Each dragon weighs in excess of 35 tonnes with the fiber glass cladding panels covered in 2163m2 of 24kt Gold Leaf.

One of the main highlights of the Wynn Palace Lake is a fantastic pair of golden dragons. The golden dragons function as deflection towers for the gondola ride around the Wynn Palace Lake and act as a symbol of good luck for guests visiting the casino.

The dragons were built exclusively in our Montreal workshops over a period of 18 months and installed in Macau by our Installation team.

The Sun Kinetic sculpture – Rio Olympic Games 2016

We were really excited to fabricate this Anthony Howe’s kinetic sculpture. This complex mechanical piece of equipment weighs 2826 kg (6231 lb) with an overall diameter of 10 meters (33 feet) from tip to tip.

It is made of aluminum, steel and fibreglass. It operates with 2 electrical motors and can rotate up to 5 rotations per minute. Its shiny look is accentuated with polished aluminum, chrome wrapping and special mirror paint.

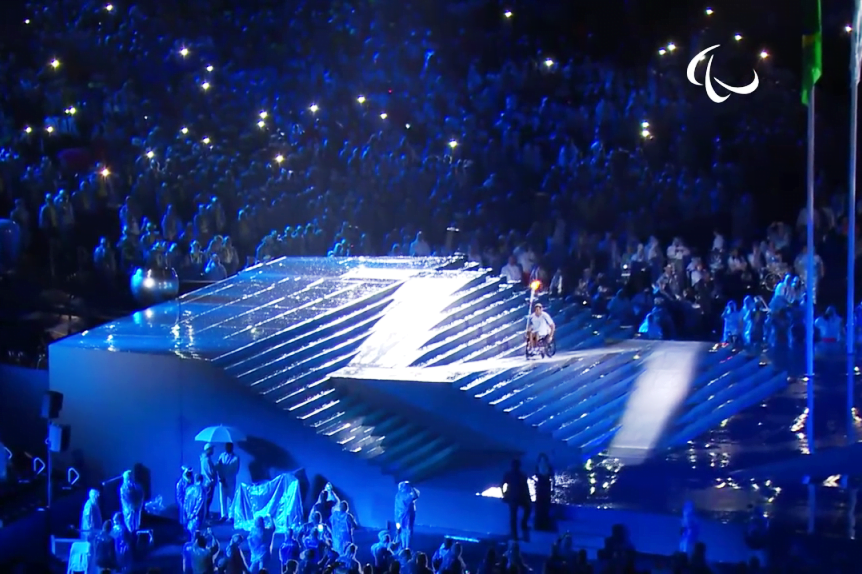

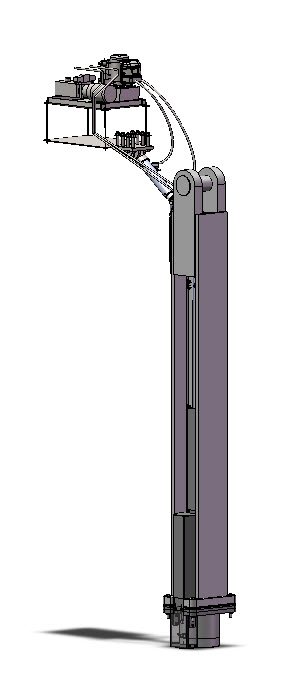

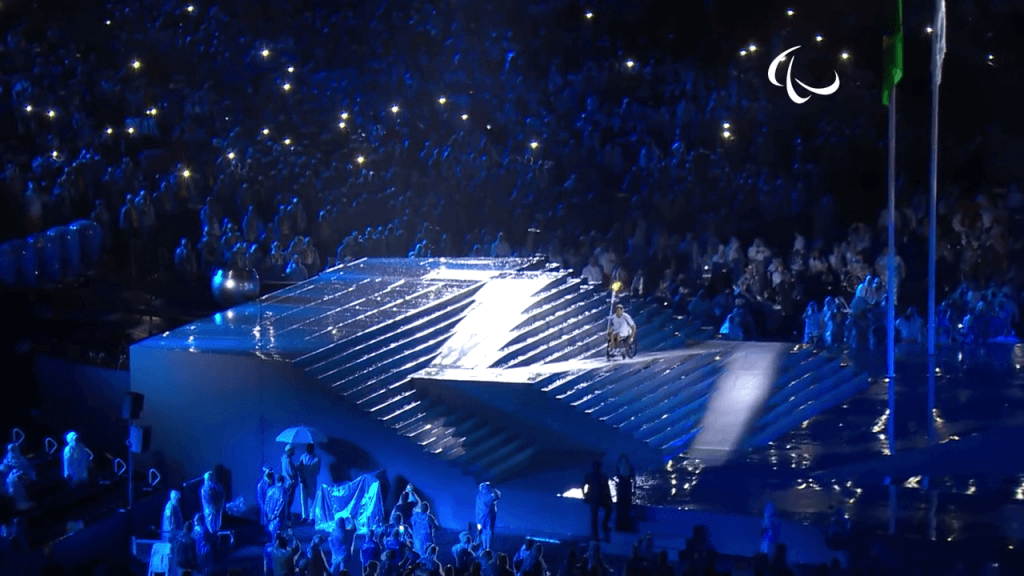

Automated staircase for Rio Paralympics Games 2016

As part of the Rio 2016 Paralympic Games, we made this retractable staircase.

The staircase is located in the rear central part of the stage and is designed to transform itself from a regular flight of stairs into 3 wheelchair ramps.

The staircase is kept in a closed position at the beginning of the show, and then its automated system moves the front section out, creating a ramp allowing wheelchair access to the athlete who can therefore attain and ignite the Olympic Cauldron. See video at 3:49:35

Kinetic Sculpture – Concept by Anthony Howe

Within a second collaboration with the artist Anthony Howe, after The Sun, as part of the 2016 Rio Olympic Games, we were please to produced this kinetic sculpture named Di-Octo. Being entirely made up of 316 stainless steel plates, this has the property of offering high corrosion resistance as well as non-magnetic properties.

Concordia University chancellor Jonathan Wener and his wife, Susan Wener, have donated the sculpture to the university and the city for Montreal’s 375th anniversary and Canada’s 150th anniversary celebrations. The sculpture is seen outside Concordia’s Hall Building at Mackay St. and de Maisonneuve Blvd. in Montreal. (Photo credit : John Mahoney / Montreal Gazette).

This sculpture is made up of 36 branches (containing 16 very fine steel cupolas) revolving around a circular axis. It weighs 1400 lbs (635 kg) and is 22 feet high (10.6m) per 10.3 ¾ feet (3.15m) diameter. This sculpture may be activated by a wind of 1 mph (1.6 km/h) and can resist winds up to 90 mph (144 km/h).

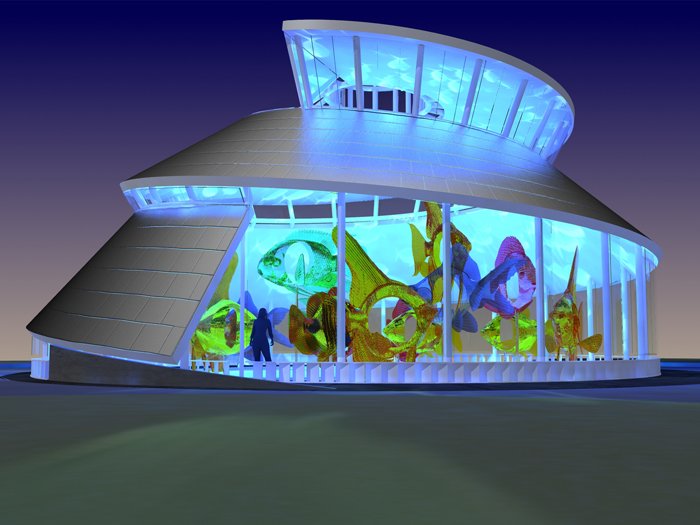

Seaglass Building Structure

The structure of the SeaGlass Carousel located at the Battery in Manhattan NY was conceived by WXY Architecture. Similar to the Nautilus (mollusk with a spiral shell), its design presented a great challenge due to the unique shape of its structure. The exterior of the SeaGlass Carousel is made of steel tubes and glass all around at ground floor, sitting on bases with incorporated louvers. Clerestory windows, skylight and cylinder glass complete the curved structure with its laminated glass top oculus of a 3m diameter. 450 stainless steel roof shingles all custom made and stainless steel flashing complete the finish of this special building.

Seaglass Carousel – Battery Park, New York

Show Canada is proud of the realization of the Seaglass Carousel at the Battery in Manhattan NY. This innovative, aquatic-themed ride is offered to New Yorkers of all ages and tourists from around the world. The visitors find themselves within a musical seashell structure of 30 illuminated fish of different changing sparkling colors and species that are up to 4.5 m tall, made of translucent fibreglass reminiscent of frosted colored pebbles of sea glass. 18 of which moving upwards, downwards and rotating in 4 different axes reaching a height of approximately one meter high fixed on 4 motorized turntables, one of which rotates at 360° and the others rotating at 180°. The other 12 static fish are divided in 3 groups of which 2 of them can accommodate wheelchair access. Our talented team composed of professionals and technicians of various specialties is thankful to have participated in the creation of such a monumental piece of art!

Wynn Macau Kinetic Atrium

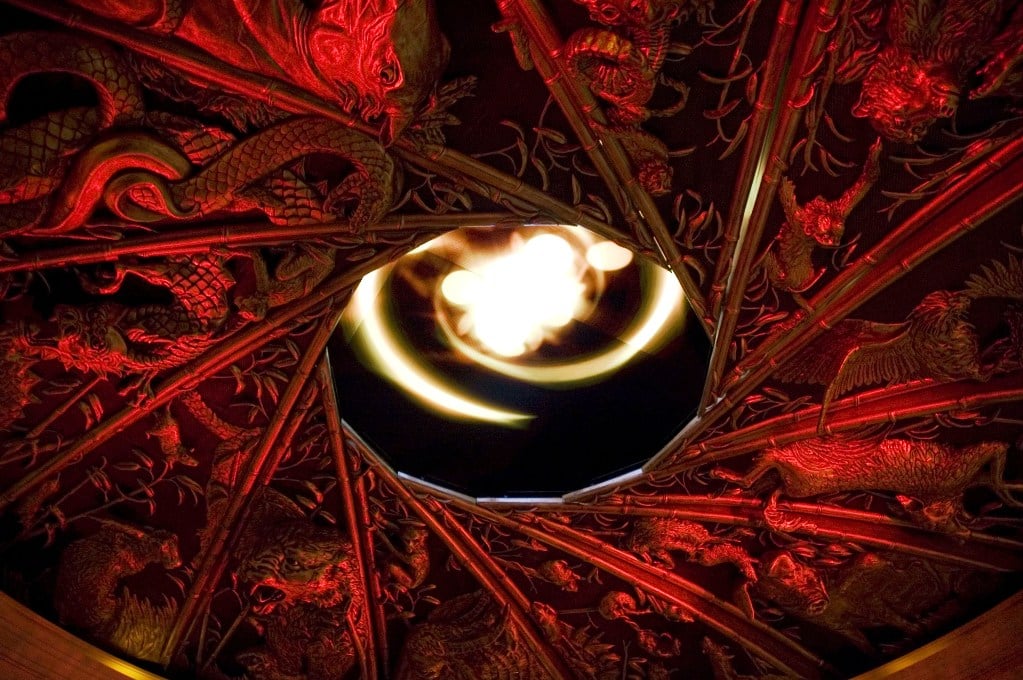

Iris

The Iris Ceiling consists of twelve (12) Wedges that, when closed, form a seamless ceiling over the Atrium. The frames clear span a 20M diameter opening in the ceiling of the Atrium, directly above the Copper Dome. The Wedges each support figures from the Chinese Horoscope.

The frames are tracked out away from the center of the atrium at a slight angle to one another, opening to reveal the LED ceiling, and then the Chandelier. The action of the twelve wedges simultaneously tracking away from a center point creates the illusion of an iris lens.

Wynn Macau Kinetic Atrium

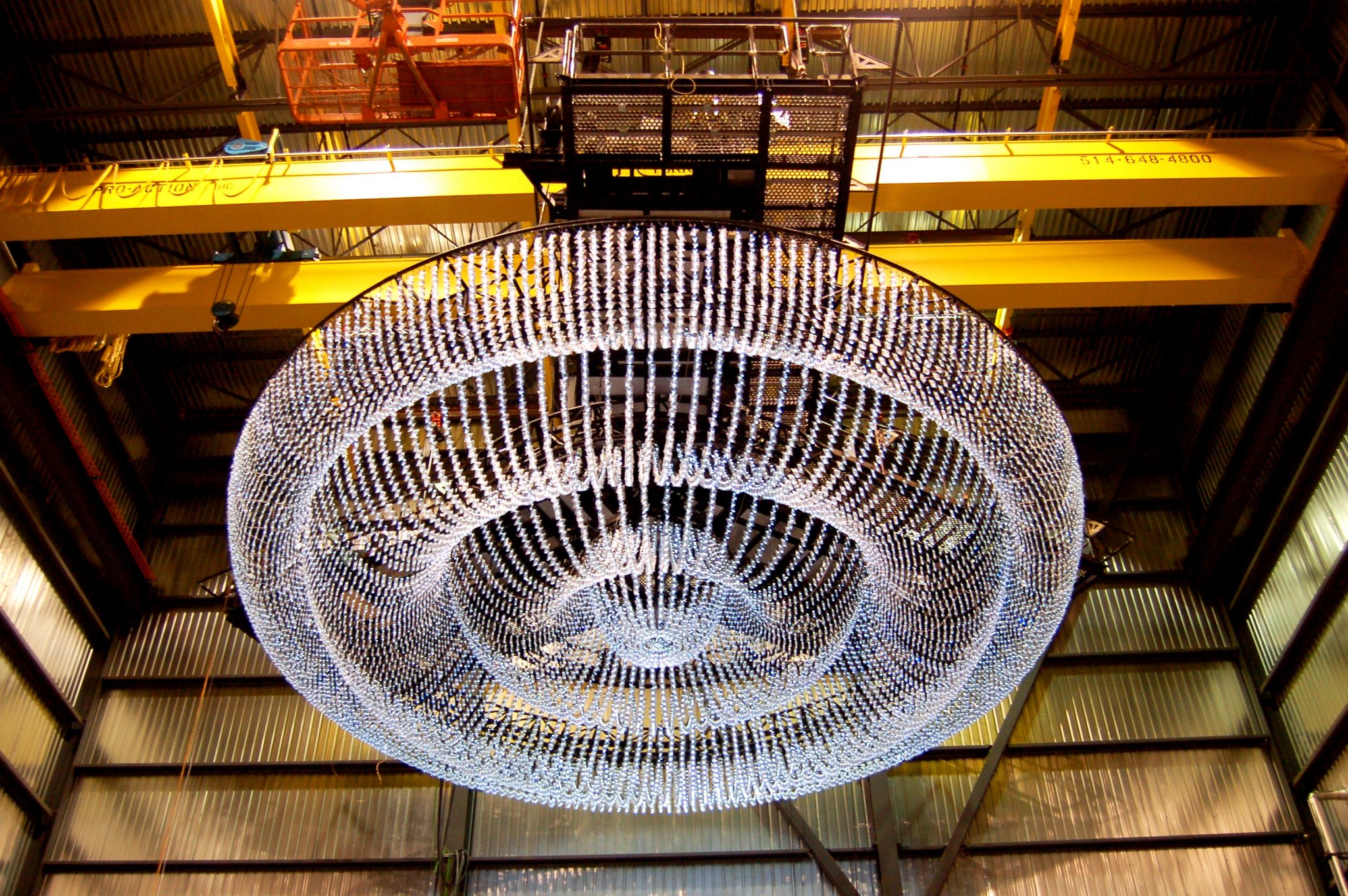

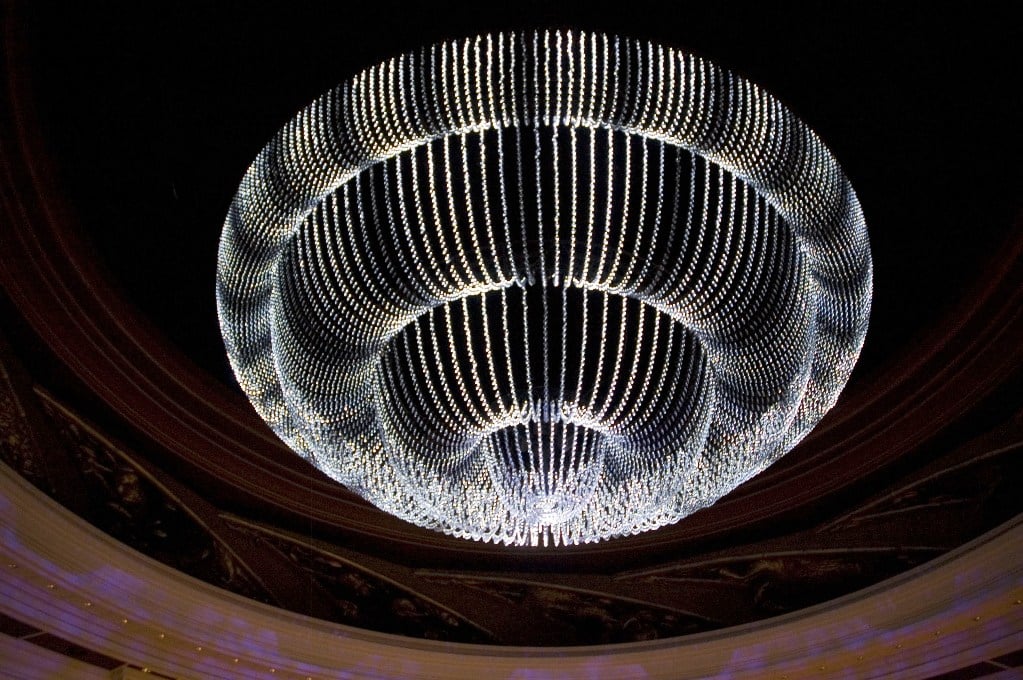

Chandelier

The chandelier is a 30 ft (9 m) diameter steel truss structure made up of four concentric rings. The rings are supported by cable winch and can be actuated in unison or as an array. The chandelier contains 21,000 crystals, each containing a light-emitting diode (LED).

Wynn Macau Kinetic Atrium

Dome

The Copper Dome is an artistically finished dome that is actually an articulating iris. The dome is divided into six (6) spiral cut leaves, which are mounted on single pivot hinges. When the leaves are closed, the dome is a complete shell which obscures the lift and wagons in the pit below. During the show, the leaves are pivoted open with large linear actuators. The action is such that all 6 leaves open like an iris to reveal the lift. The leaves rotate back and down, in order for each neighbor leaf to clear one another.

Once the Copper Dome is open, the lift is free to ascend and descend. When the lift has descended at the end of the show and the tree is clear of the Copper Dome, the Copper Dome leaves are pivoted back into place, forming the complete dome again.

Each leaf is driven by an electric linear actuator, coupled with a pneumatic cylinder. The actuator pushes a clevis that is mounted to the leaf structure at a distance from the pivot point, and the actuator itself pivots during the travel to allow the dome leaf to pivot down and out.

Comerica Park Entrance

The main entrance of Detroit Tigers Comerica Park Stadium represents Show Canada’s first big project. The project consists of architectural and decorative elements. In addition to the entrance sculptures, there are other decorative elements that constitute the project. Delivery: April 2000. Production time: 10 months.

The stadium entry consists of canopies, columns and steel doors with metallic finish. The giant steel baseball bats are 80 feet/25m tall.

Tiger sculptures are made of polyurethane foam and covered with fiberglass (GFRC). Some of them are up to 15 feet/4.5m high.

The Tree of lights – Cavalia Illumi

Illumi’s emblem of Illumi visible at kilometers around.

Like a lighhouse, the majestic tree of lights delights and enchants you in the universe of Illumi with its presence, its magic and its luminosity. The structure is 47 m high, it is the size of the Statue of Liberty!

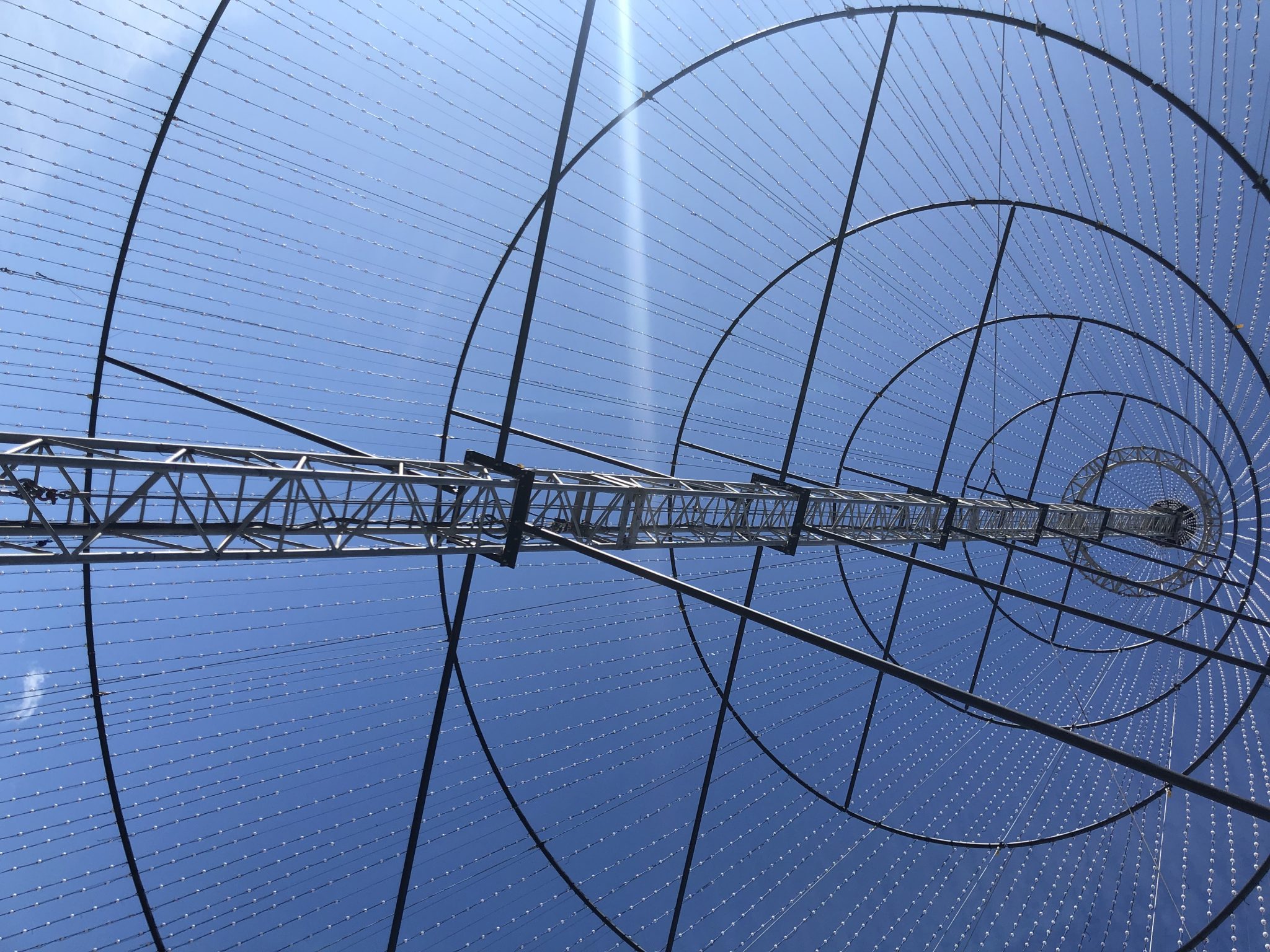

The rings are formed from bent steel tubes, bolted together to form rings. They are attached to each other by steel cables (wires). The largest ring is 65 ‘in diameter. The 3 doors are made of steel tubes, bent at the base, to give access to the interior of the tree, since the structure is large enough to accommodate a park under the top. 28,000 light and interactive spheres were hung on it.

Main Ramp Lift – Sochi Olympic games

The athletes appear in the center of the arena in front of the audience by means of our Ramp Lift. Athletes come out from under the stage and get to the circle of honour, which is brightly lit like a fashion catwalk.

They parade in front of the VIP box, make a circle around the stadium and take seats on the special tribune. This is first time in history of the Olympic Games Ceremonies that athletes appear on stage from the center stage.

The ramp lift consists of eight (8) fully independent platforms creating an access ramp for athletes during the ceremonies. Each lift platform can be actuated independently which allows to create various lift movement effects.

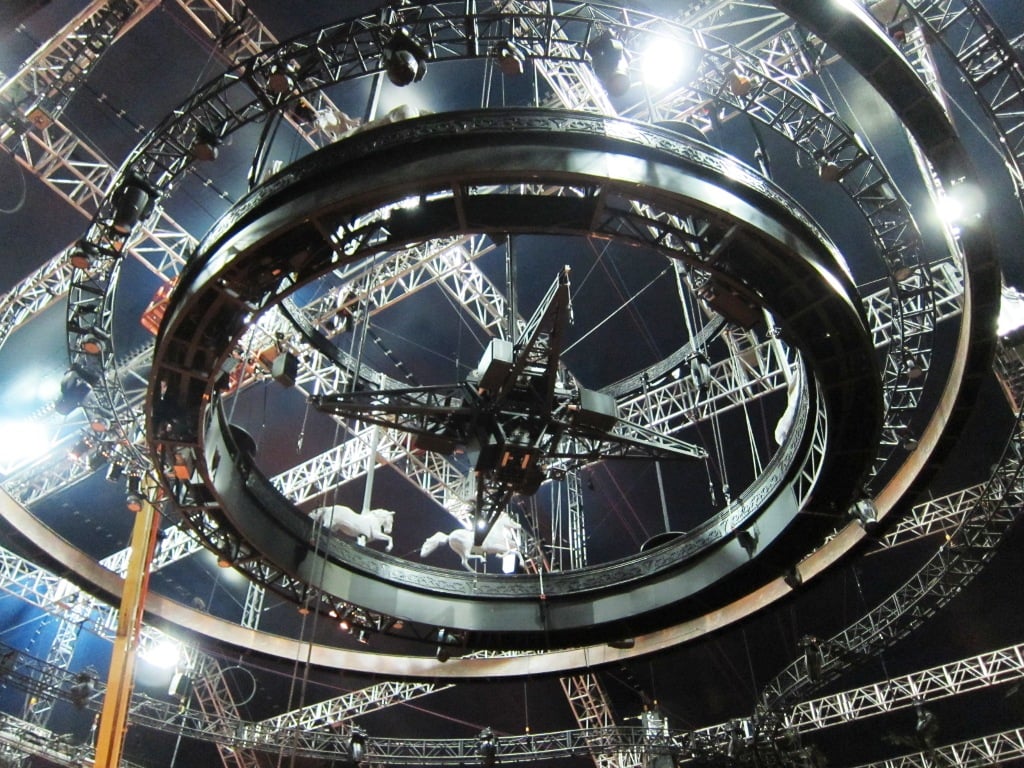

Carousel, Vol-à-Quatre and Acrobatic winch – Odysseo, Cavalia

Design, manufacture and installation of components for the 2nd art show Cavalia “Odysséo“.

The “Carrousel“ was designed and constructed to meet the artistic and technical requirements. This is a merry-go-round type carousel, composed of three different artistic elements that are three (3) rotating masts, three (3) horses with an up and down motion and three (3) fixed horses. The fixed horses also act as structural columns. The structure of the carousel is made of steel and alumium. Three motor rotates the carousel. Each rotating mast is driven by a motor and the up and down motion of the horses is provided by an aluminum track.

The “Vol-à-Quatre” was also designed and built to meet the artistic and technical requirements. It consists of an aluminum frame which includes four arms. The chassis supports five acrobatic winches. Each winch assembly / arm can withstand 200lbs and “fly” an artist at a maximum speed of 10 ft/sec. The outer diameter of “Vol-à-Quatre” is 22’2 “/ 6.75m and its mounting bearing allows rotation of 6.5 rpm. Rotation is produced by the movement of the horses and artists only.

The acrobatic winch is designed to be used directly with the artists. It has a capacity of 400 pounds at a speed of 10 ft / sec. It is equipped with a zero fleet angle device, a variable speed controler, a primary brake mounted directly on the motor and an electro magnetic brake mounted directly on the drum shaft.